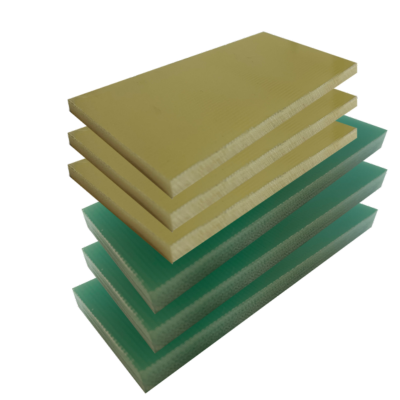

Phenolic paper laminated - Sheets HP 2061, PFCP 201

Rigid boards PFCP 201

NORMATIVE REFERENCES

Paper-phenolic laminated sheets PFCP 201 meet requirements of:

| PF CP 201 | acc. to IEC 60893 |

| Hp 2061 | acc. to DIN 7735 |

| X , XP , XPC | acc. to ANSI-NEMA IM 60000 |

COMPOSITION

Paper-phenolic laminated sheets PFCP 201 consist of cellulose paper with phenolic resin binder.

CHARACTERISTICS AND APPLICATIONS

Paper-phenolic laminated sheets PFCP 201 are characterized by good mechanical properties and good X-ray translucence. They are intended for mechanical and LV electrical applications.

MACHINING

The boards can be machined by cutting, turning, milling, and drilling. They can be effectively cut with water jet, allowing curved shapes with adequate strength. They can also be bonded using standard two-component epoxy adhesive; however, the bonded joints should not be excessively stressed.

We can also produce cut-to-size pieces or products according to technical documentation / drawing.

TECHNICAL DATA

| Property | Test method | Unit | Average results |

|---|---|---|---|

| Flexural strength | ISO 178 | MPa | 230 |

| Modulus of elasticity in flexure | ISO 178 | GPa | 13.2 |

| Compressive strength | ISO 604 | MPa | 391 |

| Tensile strength | ISO 527 | MPa | 179 |

| Shearing strength | IEC 60893 | MPa | 33 |

| Breakdown voltage at 90 °C in oil parallel to laminations | IEC 243-1 | kV | 44 |

| Comparative tracking index CTI | IEC 112 | - | 180 |

| Water absorption (sample thickness 3.0 mm) | IEC 62 | mg | 250 |

| Density | ISO 1183 | g/cm³ | 1.41 |

| Flammability | UL94 | category | HB |

THICKNESS

0.2-200 mm

TOLERANCES

Width and length tolerance: ±20 mm

COLOUR

dark brown

Phenolic cotton laminated - Sheets Hgw 2082, PFCC 201

Rigid boards PFCC 201

NORMATIVE REFERENCES

Cotton-phenolic laminated sheets PFCC 201 meet requirements of:

| PF CC 201 | acc. to IEC 60893 |

| HGW 2082 | acc. to DIN 7735 |

| C | acc. to ANSI/NEMA IM-60000 |

COMPOSITION

Cotton-phenolic laminated sheets PFCC 201 consist of cotton fabric and phenolic resin binder.

CHARACTERISTIC AND APPLICATIONS

Cotton-phenolic laminated sheets PFCC 201 are suitable for mechanical applications and are characterized by very good machining properties. Laminates are designed for continuous operation at temperatures up to 120°C.

TECHNICAL DATA

| Property | Test method | Unit | Average results |

|---|---|---|---|

| Flexural strength | ISO 178 | MPa | 142 |

| Impact strength (Charpy) notched | ISO 179/3C | kJ/m2 | 9,7 |

| Impact strength (Charpy) unnotched | ISO 179/3C | kJ/m2 | 35 |

| Modulus of elasticity in flexure | ISO 178 | GPa | 8,2 |

| Compressive strength | ISO 604 | MPa | 300 |

| Tensile strength | ISO 527 | MPa | 83 |

| Shearing strength | IEC-893-2 | MPa | 60 |

| Electric strength at 90 °C in oil perpendicular to laminations (sample thickness 3,0 mm) | IEC 243-1 | kV/mm | 1,27 |

| Breakdown voltage at 90 °C in oil parallel to laminations | IEC 243-1 | kV | 4,3 |

| Insulation resistance after immersion in water | IEC 167 | MΩ | 2,8×101 |

| Comparative tracking index | IEC 112 | - | 150 |

| Water absorption (sample thickness 3,0 mm) | IEC 62 | mg | 200 |

| Density | ISO 1183 | g/cm3 | 1,37 |

COLOUR

Brown

Glass-epoxy laminated - Sheets G10, Hgw 2372, EPGC 201

Glass-epoxy rigid boards EPGC 201

NORMATIVE REFERENCES

Glass-epoxy laminated sheets EPGC 201 meet requirements of:

| EPGC 201 | acc. to IEC 60893 |

| HGW2372 | acc. to DIN7735 |

| G-10 | acc. to ANSI/NEMA IM 60000 |

COMPOSITION

Glass-epoxy laminated sheets EPGC 201 consist of glass fabric with epoxy resin binder.

CHARACTERISTIC AND APPLICATIONS

Glass-epoxy laminated sheets EPGC 201 are characterized by good mechanical and electrical properties. They are intended for mechanical, electrical and electronic applications, where long-term thermal endurance in temperature about 130°C is critical.

TECHNICAL DATA

| Property | Test method | Unit | Average results |

|---|---|---|---|

| Flexural strength | ISO 178 | MPa | 525 |

| Impact strength (Charpy) | ISO 179/3C | kJ/m2 | 81 |

| Modulus of elasticity in flexure | ISO 178 | GPa | 22,9 |

| Compressive strength | ISO 604 | MPa | 626 |

| Tensile strength | ISO 527 | MPa | 410 |

| Shearing strength | IEC-893-2 | MPa | 47 |

| Electric strength at 90 °C in oil perpendicular to laminations (sample thickness 3,0 mm) | IEC 243-1 | kV/mm | 16 |

| Breakdown voltage at 90 °C in oil parallel to laminations | IEC 243-1 | kV | 60 |

| Insulation resistance after immersion in water | IEC 167 | MΩ | 2,4×106 |

| Comparative tracking index | IEC 112 | - | 200 |

| Permittivity | IEC 250 | - | 5,0 |

| Dissipation factor | IEC 250 | - | 0,009 |

| Water absorption (sample thickness 3,0 mm) | IEC 62 | mg | 6,0 |

| Density | ISO 1183 | g/cm3 | 1,89 |

| Thermal conductivity | ISO 8302 | W/mK | 0,44 |

| Coefficient of thermal expansion at X direction MD | Dilatometry | 10-5/K | 1,4 |

| Coefficient of thermal expansion at Y direction CD | Dilatometry | 10-5/K | 1,2 |

| Coefficient of thermal expansion at Z direction (perpendicular to laminations) | Dilatometry | 10-5/K | 6,1 |

Glass-epoxy laminated - Sheets G11 (155 °C), Hgw 2372.4, EPGC 203

Rigid boards EPGC 203

NORMATIVE REFERENCES

Glass-epoxy laminated sheets EPGC 203 meet requirements of:

| EPGC 203 | acc. to IEC 60893 |

| HGW2372.4 | acc. to DIN7735 |

| G-11 | acc. to ANSI/NEMA IM-60000 |

COMPOSITION

Glass-epoxy rigid boards EPGC 203 consist of glass fabric and epoxy resin binder.

CHARACTERISTIC AND APPLICATIONS

Glass-epoxy laminated sheets EPGC 203 are characterized by very good thermal endurance properties and high mechanical strength at elevated temperature. They are intended for mechanical, electrical and electronic applications, where long-term thermal endurance in temperatures about 155°C is critical.

TECHNICAL DATA

| Property | Test method | Unit | Average results |

|---|---|---|---|

| Flexural strength | ISO 178 | MPa | 485 |

| Flexural strength at 150°C after conditioning: 1 h at 150°C | ISO 178 | MPa | 296 |

| Impact strength (Charpy) | ISO 179/3C | kJ/m2 | 86 |

| Modulus of elasticity in flexure | ISO 178 | GPa | 25,4 |

| Compressive strength | ISO 604 | MPa | 562 |

| Tensile strength | ISO 527 | MPa | 398 |

| Shearing strength | IEC-893-2 | MPa | 51,2 |

| Electric strength at 90 °C in oil perpendicular to laminations (sample thickness 3,0 mm) | IEC 243-1 | kV/mm | 14,7 |

| Breakdown voltage at 90 °C in oil parallel to laminations | IEC 243-1 | kV | 60 |

| Insulation resistance after immersion in water | IEC 167 | MΩ | 3,0×107 |

| Comparative tracking index | IEC 112 | - | 187 |

| Permittivity | IEC 250 | - | 5,1 |

| Dissipation factor | IEC 250 | - | 0,014 |

| Water absorption (sample thickness 3,0 mm) | IEC 62 | mg | 8,8 |

| Density | ISO 1183 | g/cm3 | 1,87 |