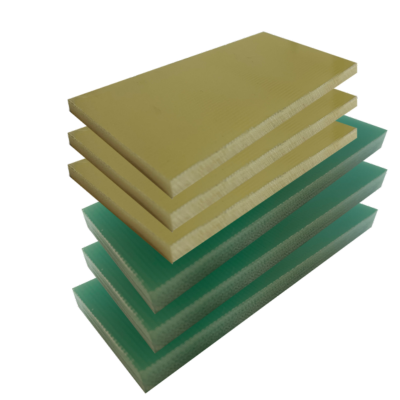

Glass Epoxy Laminated Sheet - G11 (155°) Hgw 2372.4, EPGC 203

18.0 ×

1020 ×

1020 mm

In Stock

534,60 EUR

Rigid boards EPGC 203

NORMATIVE REFERENCES

Glass-epoxy laminated sheets EPGC 203 meet requirements of:

| EPGC 203 | acc. to IEC 60893 |

| HGW2372.4 | acc. to DIN7735 |

| G-11 | acc. to ANSI/NEMA IM-60000 |

COMPOSITION

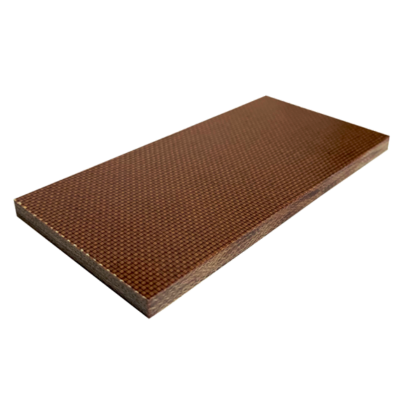

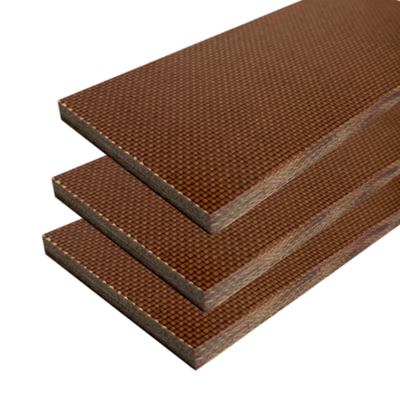

Glass-epoxy rigid boards EPGC 203 consist of glass fabric and epoxy resin binder.

CHARACTERISTIC AND APPLICATIONS

Glass-epoxy laminated sheets EPGC 203 are characterized by very good thermal endurance properties and high mechanical strength at elevated temperature. They are intended for mechanical, electrical and electronic applications, where long-term thermal endurance in temperatures about 155°C is critical.

TECHNICAL DATA

| Property | Test method | Unit | Average results |

|---|---|---|---|

| Flexural strength | ISO 178 | MPa | 485 |

| Flexural strength at 150°C after conditioning: 1 h at 150°C | ISO 178 | MPa | 296 |

| Impact strength (Charpy) | ISO 179/3C | kJ/m2 | 86 |

| Modulus of elasticity in flexure | ISO 178 | GPa | 25,4 |

| Compressive strength | ISO 604 | MPa | 562 |

| Tensile strength | ISO 527 | MPa | 398 |

| Shearing strength | IEC-893-2 | MPa | 51,2 |

| Electric strength at 90 °C in oil perpendicular to laminations (sample thickness 3,0 mm) | IEC 243-1 | kV/mm | 14,7 |

| Breakdown voltage at 90 °C in oil parallel to laminations | IEC 243-1 | kV | 60 |

| Insulation resistance after immersion in water | IEC 167 | MΩ | 3,0×107 |

| Comparative tracking index | IEC 112 | - | 187 |

| Permittivity | IEC 250 | - | 5,1 |

| Dissipation factor | IEC 250 | - | 0,014 |

| Water absorption (sample thickness 3,0 mm) | IEC 62 | mg | 8,8 |

| Density | ISO 1183 | g/cm3 | 1,87 |