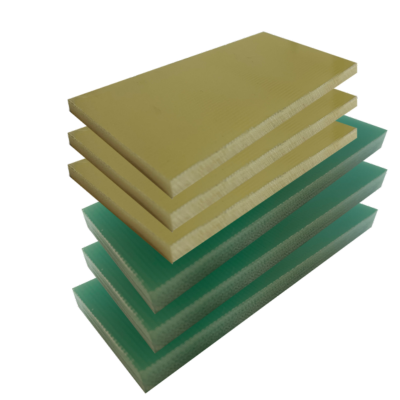

Glass Epoxy Laminated Sheet - G10 (130 °C), HGW 2372, EPGC 201

50.0 ×

1020 ×

1020 mm

In Stock

1 310,20 EUR

Glass-epoxy rigid boards EPGC 201

NORMATIVE REFERENCES

Glass-epoxy laminated sheets EPGC 201 meet requirements of:

| EPGC 201 | acc. to IEC 60893 |

| HGW2372 | acc. to DIN7735 |

| G-10 | acc. to ANSI/NEMA IM 60000 |

COMPOSITION

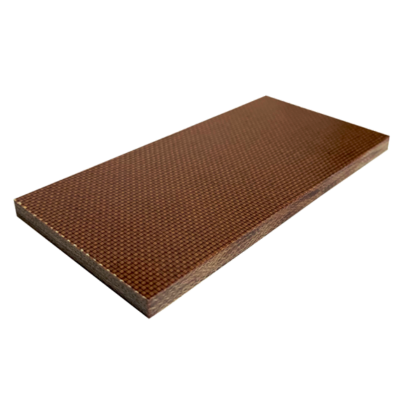

Glass-epoxy laminated sheets EPGC 201 consist of glass fabric with epoxy resin binder.

CHARACTERISTIC AND APPLICATIONS

Glass-epoxy laminated sheets EPGC 201 are characterized by good mechanical and electrical properties. They are intended for mechanical, electrical and electronic applications, where long-term thermal endurance in temperature about 130°C is critical.

TECHNICAL DATA

| Property | Test method | Unit | Average results |

|---|---|---|---|

| Flexural strength | ISO 178 | MPa | 525 |

| Impact strength (Charpy) | ISO 179/3C | kJ/m2 | 81 |

| Modulus of elasticity in flexure | ISO 178 | GPa | 22,9 |

| Compressive strength | ISO 604 | MPa | 626 |

| Tensile strength | ISO 527 | MPa | 410 |

| Shearing strength | IEC-893-2 | MPa | 47 |

| Electric strength at 90 °C in oil perpendicular to laminations (sample thickness 3,0 mm) | IEC 243-1 | kV/mm | 16 |

| Breakdown voltage at 90 °C in oil parallel to laminations | IEC 243-1 | kV | 60 |

| Insulation resistance after immersion in water | IEC 167 | MΩ | 2,4×106 |

| Comparative tracking index | IEC 112 | - | 200 |

| Permittivity | IEC 250 | - | 5,0 |

| Dissipation factor | IEC 250 | - | 0,009 |

| Water absorption (sample thickness 3,0 mm) | IEC 62 | mg | 6,0 |

| Density | ISO 1183 | g/cm3 | 1,89 |

| Thermal conductivity | ISO 8302 | W/mK | 0,44 |

| Coefficient of thermal expansion at X direction MD | Dilatometry | 10-5/K | 1,4 |

| Coefficient of thermal expansion at Y direction CD | Dilatometry | 10-5/K | 1,2 |

| Coefficient of thermal expansion at Z direction (perpendicular to laminations) | Dilatometry | 10-5/K | 6,1 |